This is the second installment of our complete Datsun 240Z Carburetor Guide, and in this particular guide we’ll be showing you how to remove your 240Z’s SU carburetors so that you can clean and rebuild them in the next installment. Removal of the SU carburetors from the 240Z engine can be confusing as there are many different components which connect to the carburetors, but we will be walking you through removing everything step-by-step.

Quick note for my readers: some of the links on this page may be affiliate links, meaning I receive a commission (at no extra cost to you) if you click on the link and make a purchase. I only recommend products I’ve used and trust unless stated otherwise. Below you will find some recommended tools and books for this SU carburetor removal process, with corresponding links to these products if you do not have them already.

If you would prefer to watch a video of this removal process instead, ZCarGuide also has a video guide of this process which is embedded below or you can just watch directly on YouTube by clicking this link.

Recommended Tools and Resources

- SU Carburetors Tuning Tips & Techniques — This book is an extremely helpful resource for those who want to understand how their SU carburetors function, the physics behind operation, in-depth troubleshooting, and much more technical advice. This book is a must-have for someone who wants to understand what’s going on with their SU carburetors.

- Haynes 240Z, 260Z, and 280Z Repair Manual — Every Datsun Z-car owner or mechanic needs the Haynes manual in his garage. The Haynes Manual is fantastic for visualizing the job at hand — it has the best exploded diagrams of any of the manuals listed here. Nearly every page includes helpful diagrams and imagery that will make a huge difference. This guide is very handy when it comes to working with your carburetors.

- Ratchet with 1/2″ Drive

- 3″ Ratchet Extension

- 12mm Socket

- 14mm Wrench

- Needle Nose Pliers

Removing the Air Cleaner

The first thing you will need to do is get the air cleaner out of the way. You can start by removing the two thumb screws holding the air cleaner housing on to the backing plate. Once they’re completely removed, you can let them sit and lift the air cleaner housing straight upwards and out of the engine bay. Make sure you don’t lose the thumb screws or the air cleaner element during this process.

The air cleaner backing plate will still be attached to the carburetors. You will need to grab a 14mm wrench to grab out the bolts with the longer heads, and a ratchet with a 12mm attachment (an extension is also likely necessary) to remove the regular bolts with the screw face. You can probably remove these directly out without having to worry about catching the backing plate, as it will be held up by a series of hoses, mainly the large hose which attaches to the valve cover.

Next, we’ll be removing these hoses. Before you remove any hose, make sure you are loosening any clamp it has, or you risk damaging the hose. However, it may be a good idea to replace hoses at this point if you do notice any signs of wear. Here are the hoses you will remove, in order:

- Each of the hoses which connect the float bowl to the backing plate. Remove at the float bowl end.

- The hose at the bottom of the backing plate, which connects via a protruding inlet pipe coming from the backing plate. Remove at that end.

- Finally, remove the large hose connecting to the valve cover. Remove at the valve cover end.

With that, you should be able to pull the backing plate away from the engine bay, leaving just the throttle linkage, choke, some fuel lines, and a few other components left to deal with before we can actually remove the carburetors.

Throttle Linkage, Choke Cables, and More

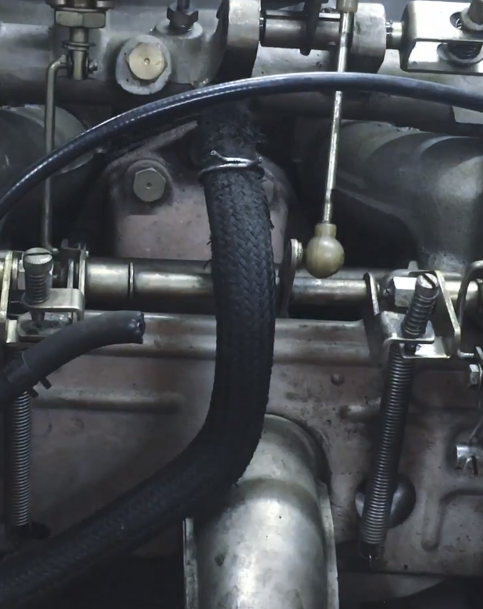

Next, we’ll be removing a few more things that will allow us to get to the carburetors themselves. First, remove the braided hose pictured here. It won’t be an issue until you have to remove the carburetors, but it will be nice to have out of the way. Simply unclamp it with a set of needle nose pliers and pull it off of the engine side.

Remove the return springs that control the throttle linkage recoil. You can hang them off of the holes next to the upside-down hanger they were originally attached to. Next, simply push off the bottom end of the ball joint that connects the pedal control to the throttle linkage. You shouldn’t need any tools, just push it off gently by hand.

If you have smog equipment, you will see a rod that attaches it to the carburetor throttle linkage, pictured here. If you remove the cotter pin and the washer behind it, you can just slide that rod out so it no longer attaches to that throttle linkage.

Next, we’ll be removing the choke. Start by removing the two set screws completely out and freeing the line. Then, you can use a screwdriver to loosen the clamp that holds the choke cable to the carburetors. With both the top and bottom screws loosened, you can simply pull the choke cable and those clamps away from the carburetors. Set the choke cables aside so they won’t be in our way when we remove the carburetors. I would also recommend making sure you screw the set screws back in so you don’t lose them.

Each carburetor has a fuel line going into the float bowl. Because we removed the lines which connected to the air cleaner, these fuel lines will actually be the only remaining hoses on the top of the carburetor float bowls. However, this time I don’t recommend removing from the carburetor end. Remove the opposite end as it is much easier to slide off, and not as much fuel will fly around once you get them free. If you want to be extra careful, grab a container to collect fuel that may remain in the lines. To actually remove the lines, you will first need to loosen the hose clamp with a flat-blade screwdriver. It may be stuck to the rubber hose, and in that case you will want to just nudge it off so you can slide it out of your way.

Removing the Carburetors

Finally, we’re going to start removing the actual carburetors and what remains of the linkage! Each carburetor is held in place with four 12mm nuts. Fortunately, you can take all of them off and the carburetor will still rest on the threaded studs. Each nut should be backed by a flat washer and a lock washer, so be sure not to lose those. With all of the nuts and washers removed, set up an area where you can set down the carburetors, as you don’t want to decide on that once you’ve picked them up! Grab the carburetors and make sure you push them together (so you hold on to the carburetor throttle linkage) and slide them back and away from the engine.

And with that, your carburetors are removed and ready to be worked on!