If you’ve tried tuning your Datsun 240Z’s SU carburetors and just can’t seem to get them to function properly, you probably need to take them apart and give them a good rebuild. Rebuilding a carburetor, let alone two of them, can be a daunting task because there are so many small parts involved and sometimes a carburetor can seem like an extremely complicated device. With this guide, we’ll show you everything step-by-step so you can get your carburetors operating like new with just a couple hours of work. This guide will require you to have the carburetors off of your 240Z, so if you need some help with removing the carburetors, we also have a guide on that! All of these guides are apart of ZCarGuide’s ultimate Datsun 240Z Carburetor Guide, so be sure to check that out to demystify any part of this process.

This guide is only applicable to ‘Round Top’ 240Z SU carburetors. Currently, we do not offer specific tuning advice for ‘Flat Top’ SU carbs. The Flat Top carbs are much more difficult to tune and many suggest simply replacing them with their Round Top variants.

If you would prefer to watch a video version of this guide, check out the video embedded below, or you can just click here to watch it right on YouTube.

Correct Rebuild Kit

While rebuilding your carburetors can be done with a pretty normal selection of hand tools that you probably already have in your garage, you will need a rebuild kit as you go through this process. The rebuild kit contains an assortment of replacement parts that you will most likely need if you want to fix whatever the underlying issue your carburetor has. Determining the exact correct rebuild kit for your carburetor is important.

Things like gaskets, washers, fuel-line hoses, the needle-and-seat assembly, and much more can be found in carburetor kits. These are all parts that can’t just be repaired, so you’ll want to just replace them outright. We sell 240Z Carburetor Kits for all years:

- 1970-1971 Datsun 240Z SU Carburetor Rebuild Kit

- 1972 Datsun 240Z SU Carburetor Rebuild KIt

- 1973 Datsun 240Z SU Carburetor Rebuild Kit

Dismantling your SU Carbs

The first step in rebuilding your carburetors is pretty simple: you’ll be tearing them apart! However, you don’t want to just remove everything you can see. There are a lot of components that you will not need to remove. Some of these just have no chance of being the point of failure, and some components are too difficult to remove without stripping screws, so we’ll just clean around those. However, we’ll outline everything you need to rebuild, and in order, so you don’t waste any time.

One thing you may want to consider: Because there will be so many little screw and washers and other small parts, it’s helpful to have some kind of organizing tray so that you don’t lose track of where things came from. This may not seem important now, but you definitely don’t want to end up with a washer lying around after you’ve put the whole carburetor back together.

- Remove the suction chamber bell housing by removing the 3 or 4 screws that contain it. These can be on very tight, so be sure you use the correct screwdriver and apply a lot of downward force so that you don’t risk stripping the screw heads. I find that it is easiest to use a flathead to get the best grip.

- Slide off the bell housing, damper spring, and suction chamber piston. It is important that you remove the piston directly upwards so you don’t damage the needle. Place all of this in your organizing tray together.

- Next, remove the top cover of the float bowl. We won’t be completely removing the float bowl assembly, but just removing the top as it is connected to the float itself. Once you have the four screws removed, you’ll need to rotate the float bowl top cover it so that you can actually remove it, as otherwise the carburetor assembly will be in your way.

- Now, we’re going to be working with the mixture screw. Remove the hose that connects the mixture jet to the bottom of the float bowl. If your hose is damaged, don’t worry — a new hose is contained in our rebuild kit.

- Use a flathead screwdriver to remove the arm that connects the choke control to the mixture jet. Be extremely careful that you do not strip this screw head.

- With the connecting arm removed, the mixture jet can be slid right out of the carburetor.

- Unscrew the mixture screw, then take off the spring and washer.

Cleaning Process

With all of the typical “problem areas” removed and dismantled, we are ready to begin cleaning everything. You need to clean everything, from the remaining carburetor assembly itself, to all of the little parts we just took off. Here’s how I prefer to do this:

- Use some Gibbs Lubricant and let it soak for a moment. This is especially useful on areas with a lot of carbon buildup and general gunk. A great complement to Gibbs is some steel wool.

- Once you’ve got the bulk of if cleaned up, use some general carburetor/choke cleaner and a brush of some kind to finish. My favorite is the Gumout brand carb cleaner.

- Dry it all off with a paper towel, making sure it isn’t catching on any rough edges and leaving some paper towel shavings behind in your carburetor!

Gasket Removal

You will likely have to remove some old gaskets on: the float bowl, the intake manifold mating surface, and the air cleaning mating surface. Sometimes there will still be large pieces of gasket on these surfaces. If you use a razor blade and gently cut the gasket pieces from the surface, it should save you a lot of time. Even after removing the large pieces with the razor blade, you will likely need to use some more Gibbs spray and steel wool to get the rest of it. As always, finish with some general carb cleaner and dry the cleaned surface.

Setting the Float Level

Before we reassemble all of this, you need to make sure the float level is set correctly. Grab the old float bowl cover assembly, and slide out the float itself by removing the spindle that holds it in place. Take a look at the float itself and see if you can spot any leaks. At this point, you might want to even drop it in a cup of water to verify that it is completely airtight and still floats as it should.

However, the most important thing you need to do at this phase is replace the old needle and seat assembly with the new one contained in the rebuild kit. Use a 10mm deep socket — you’ll need quite a bit of force to turn it free, but after that you can turn it out by hand. Insert the new needle and seat, and use the 10mm socket again to tighten it.

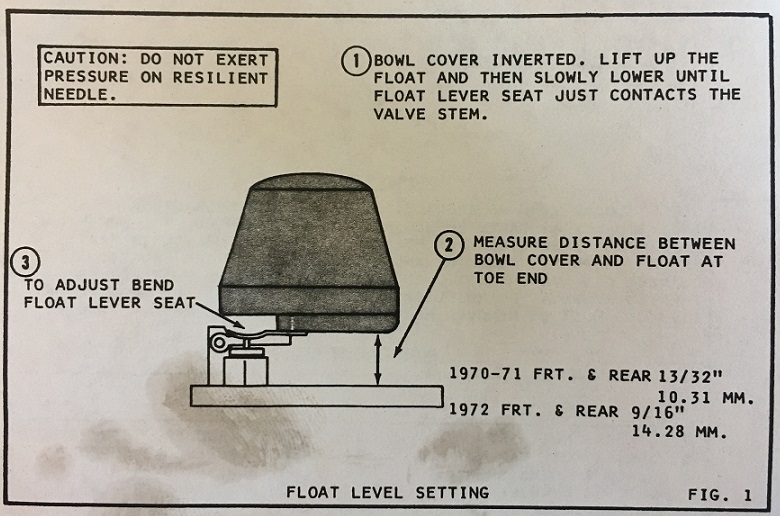

With the new needle and seat in place, install the float again by reinserting that spindle. Use the chart below to determine if your float level is accurate or not. The rebuild kit comes with a small ruler that will help you with this. You are looking for the distance between the float and the top of the bowl to be 10.31mm, and you can bend the little metal tab attached to the float to change this distance. Also remember, the chart is based off flipping this float bowl cover upside down!

Rebuilding the Carburetor

Start by reassembling the mixture jet assembly: add the washer and spring back, and screw on the mixture screw. Then you can slide the mixture jet back in, and hold it in by reattaching the choke control arm which is spring loaded, meaning the mixture jet will be held in place. You will probably need to screw the mixture screw all the way up in order to be able to do this, but if not, you should anyway, as that is the starting point for the SU carburetor tuning process.

Use the new float bowl gasket from your rebuild kit, and use it while you reattach the old float bowl cover. You will need to put it on at a different angle (90 degrees from the correct position) in order to actually fit the cover on, and then you can rotate it to the right spot. You want the side that features the fuel input to face away from the carburetor. This side will also have a little bracket, so make sure you are using the two longer screws on that side.

Next, add the suction chamber piston back in, making sure that the new needle goes in straight down and you don’t damage it. It is a very delicate component. You also want to make sure that you use a liberal amount of lubricant on the whole piston before you slide it in. From there, you can add the suction chamber dampening spring and the bell housing before securing it with the 3/4 screws. It can only go in at one orientation, so just rotate it until all the holes line up.

Unscrew the dampening rod at the very top of the bell housing and replace the old gasket with the new one provided in the rebuild kit. Slide it back into place, but do not screw it on just yet. You need to pour in some Marvel Mystery oil while the dampening rod is in place, but not completely removed. Pour the oil in until it levels out about a half inch from the top of the bell housing.